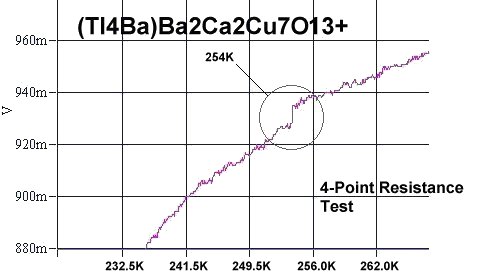

Superconductors.ORG herein reports the observation of record high superconductivity near 254 Kelvin (-19C, -2F). This critical temperature (Tc) is believed accurate +/- 2 degrees, making this the first material to enter a superconductive state at temperatures commonly found in household freezers.

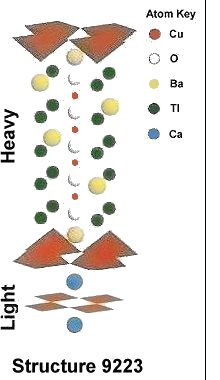

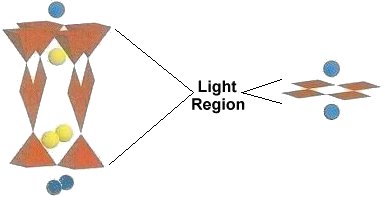

This achievement was accomplished by combining two previously successful structure types: the upper part of a 9212/2212C and the lower part of a 1223. The chemical elements remain the same as those used in the 242K material announced in May 2009. The host compound has the formula (Tl4Ba)Ba2Ca2Cu7O13+ and is believed to attain 254K superconductivity when a 9223 structure forms (shown below left).

|

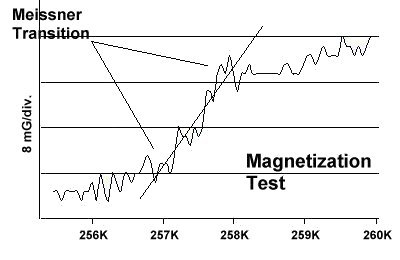

One of six magnetization tests performed on a sample pellet is shown above. In order to increase the magnetometer signal-to-noise ratio, this pellet was synthesized using the "layer-cake" method discussed here. All the tests showed a diamagnetic transition between 257K and 259K.

4-point resistance tests were performed on both a "bulk" pellet and a "layer-cake" pellet. A 254K critical transition temperature was observed on all four tests, including the plot at page top. |

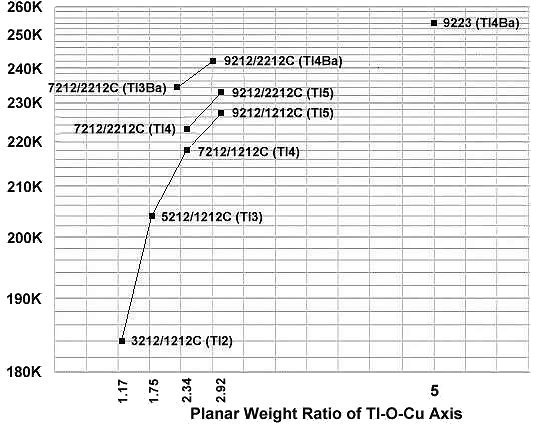

Unlike the 242K material, the 9223 is not an intergrowth structure. However, the very lopsided arrangement of atoms along the C (vertical) axis means that, like the intergrowths, planar weight disparity (PWD) is profound. Very high Tc (warm) superconductors are based on establishing a high planar weight ratio (PWR) between alternating layers (note "Heavy" and "Light" in 9223 graphic above left).

The 9212/2212C structure of the 242K material has 3 copper atoms in a chain within the "Light" part of the structure (see below left). The 1223 structure of a previous record-holding material, Hg-1223, has only a single copper atom in the "Light" area (see below right). This means the heavy-to-light ratio is several times greater when the single Cu lower structure is appended to the same upper structure. Note also that the 254K material has 16 metal layers per unit cell, which prior research has shown to be optimal. And it is 20% barium hole-doped in the thallium atomic sites - close to the ideal of 25%.

An effort was made to advance the world record even higher by adding extra Tl-Cu layers to the upper part of the structure. However, in a target 20-layer prototype, only lower order transitions appeared. No resistive transitions appeared above 254K.

On 5 January, 2010, a pellet was tested that featured cadmium doping of the thallium atomic sites, instead of barium doping (both Ba and Cd have +2 oxidation states). The new formula thus became (Tl4Cd)Ba2Ca2Cu7O13+. That formulation also produced a sharp resistive transition near 254K. However, barium remains the preferred dopant, as cadmium is prone to occupy other atomic sites (à la mercury).

To gain a sense of how "warm" 254K is, consider that it is 59 degrees

above the point where dry ice sublimates. A dot has been placed within the plot below, depicting where (Tl,Ba)-9223

lies relative to the other high performance thallium-cuprates. Note that all the curves roll over rapidly in the upper

Tc ranges.

The volume fraction of this material is very low. Before commercialization is possible, a refinement method will need to be developed to increase the VF. As a result of a low VF, numerous R-T and magnetization tests may be necessary to see the respective transitions above the noise. This discovery is being released into the public domain without patent protection in order to encourage additional research.

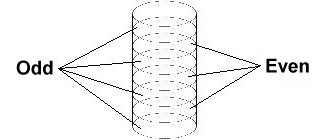

The pellet was synthesized layer cake (as shown above) using the below stoichiometric ratios for the ODD layers:

Tl2O3 99.99% (Alfa Aesar) 7.026 grains...and the below stoichiometric ratios for the EVEN layers.

CaCO3 99.95% (Alfa Aesar) 0.77 grainsThe precursors were pelletized and sintered for 34 hours at 865C. The pellet was then annealed for 10 hours at 500C in flowing O2.

The magnetometer employed twin Honeywell SS94A1F Hall-effect sensors with a tandem sensitivity of 50 mv/gauss. The 4-point probe was bonded to the pellet with CW2400 silver epoxy and used 7 volts on the primary.

RESEARCH NOTE: The copper-oxides are strongly hygroscopic. All tests should be performed immediately after annealing.

E. Joe Eck

© 2009, 2010 Superconductors.ORG

All rights reserved.

BACK to "News" page at Superconductors.ORG

BACK to "News" page at Superconductors.ORG